Saturday, November 8, 2014

Green USB switch

According to the Energy Saving Trust, if you add up all the current drawn in standby mode by items such as stereos, TVs, VCRs and DVDs over a year in the UK alone, it amounts to 3.1 million tonnes of CO2 released into the atmosphere.This is without factoring in the current drawn by all the PCs,laptops and their associated peripherals left in standby mode.

Circuit diagram :

Green USB switch Circuit Diagram

It is not necessary to spend a great deal of money or time to make a difference on a personal level. The circuit described here is designed for use by laptop or notebook computers. It will automatically switch off all mains powered peripheral equipment including monitor, printer, scanner, TV tuner and USB hub etc when it detects that the notebook is switched off. The circuit is quite straightforward; in addition to an optocoupler it requires a 12 V double-pole relay with mains rated contacts and a small power supply for the optocoupler. When the laptop is switched on 5 V appears at the USB socket, activating the relay and switching through the mains supply on K3 and K4. The notebook’s USB socket is still available to be used as normal but it’s worth remembering that the optocoupler takes a few milliamps from the USB supply and this may cause a problem if a high-current device is plugged into the USB socket. In the case where the laptop has more than enough USB sockets it may be worthwhile us-ing one of them solely for this circuit, the extension USB connector K2 would then not be required.

The circuit is mounted into a mains plug enclosure which provides a socket where the mains extension strip will be plugged into. With any luck there will be sufficient space to fit the entire circuit into the mains extension strip enclosure and save the need for a separate enclosure. The slow-blow 6.3-A fuse (F1) protects the equipment plugged into the strip.

In addition to the optocoupler and relay the circuit also has a ‘freewheel’ diode D1 and a relay driver formed by T1 and its base bias voltage divider network R2/ R4. The two ‘snubber’ networks C1/R3 and C2/R5 reduce the possibility of arcing which can occur when the relay contacts open (especially with inductive loads). Capacitors C1 and C2 must be class X2 types which can handle mains voltage plus any spikes. The power supply consists of a small mains trans-former (12 V, 50 mA), bridge rectifier and smoothing capacitor C3.

The laptop’s mains adaptor itself can also be switched by this circuit when the laptop is fitted with its rechargeable battery which allows the computer to boot up without a mains supply. The en-tire USB switch circuit draws cur-rent even when it is off but this value is tiny compared to the combined standby current of all the peripherals.

Note that parts of this circuit are connected to the (potentially lethal) mains supply voltage; it is essential to provide protection to ensure that nothing can accidentally make contact with these parts of the circuit. It is also important to observe correct separation between parts of the circuit carrying low voltage and those carrying the high volt-age. Please observe the electrical Electrical Safety guide-lines which are reprinted in Elektor Electronics several times a year.

The circuit is less suitable for use with desktop PCs be-cause the majority of these machines supply 5 V over the USB socket even though they have been shut down via soft-ware. The only way to turn off in this case is to reach around the back of the machine and switch off at the main switch.

Simple 16 Stage Bi Directional LED Sequencer

The bi-directional sequencer uses a 4 bit binary up/down counter (CD4516) and two "1 of 8 line decoders" (74HC138 or 74HCT138) to generate the popular "Night Rider" display. A Schmitt Trigger oscillator provides the clock signal for the counter and the rate can be adjusted with the 500K pot. Two additional Schmitt Trigger inverters are used as a SET/RESET latch to control the counting direction (up or down). Be sure to use the 74HC14 and not the 74HCT14, the 74HCT14 may not work due to the low TTL input trigger level. When the highest count is reached (1111) the low output at pin 7 sets the latch so that the UP/DOWN input to the counter goes low and causes the counter to begin decrementing.

When the lowest count is reached (0000) the latch is reset (high) so that the counter will begin incrementing on the next rising clock edge. The three lowest counter bits (Q0, Q1, Q2) are connected to both decoders in parallel and the highest bit Q3 is used to select the appropriate decoder. The circuit can be used to drive 12 volt/25 watt lamps with the addition of two transistors per lamp as shown below in the section below titled "Interfacing 5 volt CMOS to 12 volt loads"

Friday, November 7, 2014

Simple 7805 Voltage Regulator Circuit

A voltage regulator is used to produce a constant linear output voltage. It’s generally used with AC to DC power supply. And also it can be used as well as a DC to DC voltage converter . To regulating low voltage, most used device is one single IC. 7805, 7812, 7905 etc. 78xx series are design for positive and 79xx series are for Negative voltage regulator.

7805 is a three terminal +5v voltage regulator IC from 78XX chips family. See 7805 pinout below. LM78XX series are from National Semiconductor. They are linear positive voltage regulator IC; used to produce a fixed linear stable output voltage. National Semiconductor has also negative voltage regulator chips family, they indicate with LM 79XX. 78xx is used more than 79xx because negative voltage has a few usability purposes as we see.

I was previously posted a 5v regulated power supply circuit using 7805 IC, that circuit and this 7805 voltage regulator circuit is almost the same.

I was previously posted a 5v regulated power supply circuit using 7805 IC, that circuit and this 7805 voltage regulator circuit is almost the same.

Its output voltage is +5V DC that we need. You can supply any voltage in input; the output voltage will be always regulated +5V. But my recommendation is, don’t supply more than 18V or less than 8V in input. There used two capacitors in this voltage regulator circuit, they aren’t mandatory to use. But it will be best if you use them. They helped to produce a smooth regulated voltage at output. Use electrolyte capacitor instead of ceramic capacitor.

Thursday, November 6, 2014

Simple Automatic Headlight Brightness Switch Circuit Diagram

Going by car the highway with your high-beam headlights can actually increase your visibility, but can be a blinding hazard for other drivers. This easy circuit can be connected into your headlight swap to provide automatic swaping between high and reduced beam headlights when there is oncoming traffic. It does this by feeling the lights of that traffic. In this way, you can propel securely with your high-beams on without blinding other drivers.

Automatic Headlight Brightness Switch Circuit Diagram

- Q1 should me mounted in such a way so it points toward the front of the car with a clear line of site.

- Suitable places are on the dashboard, in the front grill, etc.

- Adjust all the pots for proper response by testing on a deserted road.

- S1 enables and disables the circuit.B1 is, obviously, in the car already.

- Before you try to connect this circuit, get a wiring diagram for your car.

- Some auto manufacturers do weird things with wiring.

- Connection A goes to the high beam circuit, B goes to the headlight switch common and C connects to the low beam circuit.

| R1 | 1 | 5K 1/4W Resistor | |

| R2, R3, R4 | 3 | 5K Pot | |

| Q1 | 1 | NPN Phototransistor | |

| Q2 | 1 | 2N3906 PNP Transistor | |

| K1 | 1 | Low Current 12V SPST Relay | |

| K2 | 1 | High Current 12V SPDT Relay | |

| S1 | 1 | SPST Switch | |

| B1 | 1 | Car Battery | |

| MISC | 1 | Case, wire, board, knobs for pots |

Intelligent Electronic Lock

This intelligent electronic lock circuit is built using transistors only. To open this electronic lock, one has to press tactile switches S1 through S4 sequentially. For deception you may annotate these switches with different numbers on the control panel/keypad. For example, if you want to use ten switches on the keypad marked ‘0’ through ‘9’, use any four arbitrary numbers out of these for switches S1 through S4, and the remaining six numbers may be annotated on the leftover six switches, which may be wired in parallel to disable switch S6 (shown in the figure).

When four password digits in ‘0’ through ‘9’ are mixed with the remaining six digits connected across disable switch terminals, energisation of relay RL1 by unauthorized person is prevented.For authorized persons, a 4-digit password number is easy to remember. To energies relay RL1, one has to press switches S1 through S4 sequentially within six seconds, making sure that each of the switch is kept depressed for a duration of 0.75 second to 1.25 seconds. The relay will not operate if ‘on’ time duration of each tactile switch (S1 through S4) is less than 0.75 second or more than 1.25 seconds.

This would amount to rejection of the code. A special feature of this circuit is that pressing of any switch wired across disable switch (S6) will lead to disabling of the whole electronic lock circuit for about one minute. Even if one enters the correct 4-digit password number within one minute after a ‘disable’ operation, relay RL1 won’t get energized. So if any unauthorized person keeps trying different permutations of numbers in quick successions for energisation of relay RL1, he is not likely to succeed. To that extent, this electronic lock circuit is fool-proof. This electronic lock circuit comprises disabling, sequential switching, and relay latch-up sections. The disabling section comprises zener diode ZD5 and transistors T1 and T2. Its function is to cut off positive supply to sequential switching and relay latch-up sections for one minute when disable switch S6 (or any other switch shunted across its terminal) is momentarily pressed.

Intelligent Electronic Lock Circuit Diagram:

During idle state, capacitor C1 is in discharged condition and the voltage across it is less than 4.7 volts. Thus zener diode ZD5 and transistor T1 are in non-conduction state. As a result, the collector voltage of transistor T1 is sufficiently high to forward bias transistor T2. Consequently, +12V is extended to sequential switching and relay latch-up sections. When disable switch is momentarily depressed, capacitor C1 charges up through resistor R1 and the voltage available across C1 becomes greater than 4.7 volts. Thus zener diode ZD5 and transistor T1 start conducting and the collector voltage of transistor T1 is pulled low. As a result, transistor T2 stops conducting and thus cuts off positive supply voltage to sequential switching and relay latch-up sections. Thereafter, capacitor C1 starts discharging slowly through zener diode D1 and transistor T1. It takes approximately one minute to discharge to a sufficiently low level to cut-off transistor T1, and switch on transistor T2, for resuming supply to sequential switching and relay latch-up sections; and until then the circuit does not accept any code.

The sequential switching section comprises transistors T3 through T5, zener diodes ZD1 through ZD3, tactile switches S1 through S4, and timing capacitors C2 through C4. In this three-stage electronic switch, the three transistors are connected in series to extend positive voltage available at the emitter of transistor T2 to the relay latch-up circuit for energising relay RL1. When tactile switches S1 through S3 are activated, timing capacitors C2, C3, and C4 are charged through resistors R3, R5, and R7, respectively. Timing capacitor C2 is discharged through resistor R4, zener diode ZD1, and transistor T3; timing capacitor C3 through resistor R6, zener diode ZD2, and transistor T4; and timing capacitor C4 through zener diode ZD3 and transistor T5 only. The individual timing capacitors are chosen in such a way that the time taken to discharge capacitor C2 below 4.7 volts is 6 seconds, 3 seconds for C3, and 1.5 seconds for C4. Thus while activating tactile switches S1 through S3 sequentially, transistor T3 will be in conduction for 6 seconds, transistor T4 for 3 seconds, and transistor T5 for 1.5 seconds.

The positive voltage from the emitter of transistor T2 is extended to tactile switch S4 only for 1.5 seconds. Thus one has to activate S4 tactile switch within 1.5 seconds to energise relay RL1. The minimum time required to keep switch S4 depressed is around 1 second. For sequential switching transistors T3 through T5, the minimum time for which the corresponding switches (S1 through S3) are to be kept depressed is 0.75 seconds to 1.25 seconds. If one operates these switches for less than 0.75 seconds, timing capacitors C2 through C4 may not get charged sufficiently. As a consequence, these capacitors will discharge earlier and any one of transistors T3 through T5 may fail to conduct before activating tactile switch S4. Thus sequential switching of the three transistors will not be achieved and hence it will not be possible to energise relay RL1 in such a situation. A similar situation arises if one keeps each of the mentioned tactile switches de-pressed for more than 1.5 seconds.

When the total time taken to activate switches S1 through S4 is greater than six seconds, transistor T3 stops conducting due to time lapse. Sequential switching is thus not achieved and it is not possible to energise relay RL1. The latch-up relay circuit is built around transistors T6 through T8, zener diode ZD4, and capacitor C5. In idle state, with relay RL1 in de-energised condition, capacitor C5 is in discharged condition and zener diode ZD4 and transistors T7, T8, and T6 in non-conduction state. However, on correct operation of sequential switches S1 through S4, capacitor C5 is charged through resistor R9 and the voltage across it rises above 4.7 volts. Now zener diode ZD4 as well as transistors T7, T8, and T6 start conducting and relay RL1 is energised. Due to conduction of transistor T6, capacitor C5 remains in charged condition and the relay is in continuously energised condition. Now if you activate reset switch S5 momentarily, capacitor C5 is immediately discharged through resistor R8 and the voltage across it falls below 4.7 volts. Thus zener diode ZD4 and transistors T7, T8, and T6 stop conducting again and relay RL1 de-energises.

Wednesday, November 5, 2014

Precise FM Tuning Indicator

Here is an add on circuit to your FM radio for precise tuning of stations. Usually an LED indicator is provided in FM radio to see whether the station is tuned or not. But it is difficult to see the precise tuning points since the variation in the LED brightness cannot be detected easily. This circuit solves the problem.

Precise FM Tuning Indicator Circuit diagram :

The circuit uses the Op Amp IC CA3140 as a differential amplifier to sense the voltage level between the terminals of the tuning LED. The output of IC1 drives two LEDs one Red and one Green to indicate whether the station is precisely tuned or not. If both LEDs remain off, it indicates precise tuning. If anyone LED is on, it indicates that tuning is not precise. If both LEDs remain on, it indicates that there is no signal.

First tune the FM receiver in a station having strong signal. The tuning LED will light brilliantly. Then connect point A and B to the soldering points of the tuning LED observing polarity. Adjust VR till both the Red and Green LEDs turn off. Slowly change the tuning knob position. Any one LED will light up. So the circuit is working. Now glue the wiper of VR using adhesive to prevent its position change. Disconnect the tuning LED from the board. Now the circuit is ready to use. Power for the circuit can be obtained from the power supply of FM radio.

High Voltage Generator

This high voltage generator was designed with the aim of testing the electrical break-down protection used on the railways. These protection measures are used to ensure that any external metal parts will never be at a high voltage. If that were about to happen, a very large current would flow (in the order of kilo-amps), which causes the protection to operate, creating a short circuit to ground effectively earthing the metal parts. This hap-pens when, for example, a lightning strike hits the overhead line (or their supports) on the railways.

This generator generates a high voltage of 1,000 V, but with an output current that is limited to few milliamps. This permits the electrical breakdown protection to be tested with-out it going into a short circuit state. The circuit uses common parts throughout: a TL494 pulse-width modulator, several FETs or bipolar switching transistors, a simple 1.4 VA mains transformer and a discrete voltage multiplier. P1 is used to set the maximum current and P2 sets the output voltage.

High Voltage Generator Circuit Diagram

The use of a voltage multiplier has the advantage that the working voltage of the smoothing capacitors can be lower, which makes them easier to obtain. The TL494 was chosen because it can still operate at a voltage of about 7 V, which means it can keep on working even when the batteries are nearly empty. The power is provided by six C-type batteries, which keeps the total weight at a reason-able level.

The 2x4 V secondary of AC power transformer (Tr1) is used back to front. It does mean that the 4 V winding has double the rated voltage across it, but that is acceptable because the frequency is a lot higher (several kilo-Hertz) than the 50 Hz (60 Hz) the transformer is designed for. The final version also includes a display of the output voltage so that the breakdown volt-age can be read.

From a historical perspective there follows a bit of background information. In the past a different system was worked out. Every high-voltage support post has a protection system, and it isn’t clear when the protection had operated and went into a short-circuit state due to a large current discharge.

Since very large currents were involved, a certain Mr. Van Ark figured out a solution for this. He used a glass tube filled with a liquid containing a red pigment and a metal ball. When a large current discharge occurred the metal ball shot up due to the strong magnetic field, which caused the pigment to mix with the liquid. This could be seen for a good 24 hours after the event. After a thunder storm it was easy to see where a discharge current took place: one only had to walk past the tubes and have a good look at them.

Unfortunately, things didn’t work out as expected. Since it often took a very long time before a discharge occurred, the pigment settled down too much. When a dis-charge finally did occur the pigment no longer mixed with the liquid and nothing was visible. This system was therefore sidelined, but it found its place in the (railway) history books as the ‘balls of Van Ark’.

Author : By Jac Hettema – Copyright : Elektor

Tuesday, November 4, 2014

Easy Make a Lights On! Schematic

This circuit ensures that you will never again forget to switch on the lights of your car. As soon as the engine is running, the dipped beams and the sidelights are automatically switched on. The circuit also causes the dipped beams to be extinguished as soon as the main beams are switched on. As you can see from the schematic diagram, no special components are needed.

When the engine is running, the alternator will generate a voltage of more than 14 V. Diode D1 reduces this voltage by 5.6 V and passes it to the base of T1 via R1. Due to the resulting current, T1 conducts. The amplified current flows via R3, the base of T3 and D3 to ground. This causes T3 to also conduct and energize relay Re1.

When the engine is running, the alternator will generate a voltage of more than 14 V. Diode D1 reduces this voltage by 5.6 V and passes it to the base of T1 via R1. Due to the resulting current, T1 conducts. The amplified current flows via R3, the base of T3 and D3 to ground. This causes T3 to also conduct and energize relay Re1.

Lights On Circuit Diagram :

If the driver now switches on the main beams, a current flows through D2 and R2 into the base of T2, causing this transistor to conduct. As a result, the voltage on the base of T3 drops, causing T3 to cut off and the relay to drop out.

When the main beams are switched off, the previous situation is restored, and the relay again engages. The dipped beams and the sidelights are switched by the contacts of relay Re1. Diodes D5 and D6 ensure that the sidelights are illuminated if either the dimmed beams or the main beams are switched on. In practice, this means that the sidelights will be on whenever the engine is running, regardless of whether the main beams are switched on.

When the main beams are switched off, the previous situation is restored, and the relay again engages. The dipped beams and the sidelights are switched by the contacts of relay Re1. Diodes D5 and D6 ensure that the sidelights are illuminated if either the dimmed beams or the main beams are switched on. In practice, this means that the sidelights will be on whenever the engine is running, regardless of whether the main beams are switched on.

Simple Mixer with 4 Input

Here the simple mixer with 4 input and 2 op-amps:

Simple Mixer with 4 Input Circuit diagram :

A basic mixer suitable for mixing microphones or even effects outputs. The overall gain from input to output is one if the pot related towards the input is full up. You can make this a net gain of ten (or any other reasonable gain) by reducing the input resistor towards the second op amp. 10K in this position gives a gain of ten, or 20db. In case you are mixing effects outputs that have an output level control constructed into them, you are able to dispense using the input level controls, or make some have level controls, some not. Audio taper pots are possibly much better, but linear will do the job.

For the op amps, choose a JFET input dual or singles, such as from the National Semi LF3xx series, or something such as the TL072 or TL082.

Security System Switcher

An audio signal can be used as a form of input to control any security system. For example, an automatic security camera can be configured to respond to a knock on the door. The circuit described here allows the security system to automatic in on state. It uses a transducer to detect intruders and a 5V regulated DC power supply provides power to the circuit.

As shown in Fig. 1, a condenser microphone is connected to the input of small signal Pre- amplifier built around transistor T1. Biasing resistor R1 determines to a large extent the microphone sensitivity. A microphone usually has an internal FET which requires a bias voltage to operate. The sound picked up by the microphone is amplified and fed to input pin 2 of IC1 (LMC555) wired in monostable configuration.

Fig. 1: Schematic Security system switcher Circuit diagram :

IC2 (CD4538B) is a dual, precision monostable multivibrator with independent trigger and reset controls. The output of IC1 is connected to the first trigger input pin 4 of IC2(A) through switch S1. If an intruder opens or breaks the door, IC1 is triggered by sound signals; the timer output pin 3 of IC1 goes high and enables first monostable multivibrator IC2(A). IC2(A) provides a time period of around 5 to 125 seconds, which is adjusted with preset VR1.

Another monostable multivibrator IC2(B) also provides a time period of around 25 to 600 seconds, which is adjusted with preset VR2. The output of IC2(B) is used to energise relay RL1. Indicator LED1 is provided to display the relay activity. Any AC/DC operated security gadget is activated or deactivated through a security switch. Thus, the security switch of the gadget is connected in the n/o contacts of the relay.You can also operate high power beacons, sirens or hooters in place of the security switch for any AC/DC operated security gadget.

Fig. 2: Proposed cabinet :

Assemble the circuit on a general-purpose PCB and enclose it in a cabinet as shown in Fig. 2 along with 5V adaptor for powering the circuit. Connect the security switch according to the circuit diagram and use appropriate AC/DC power supply required to operate the security gadget.

Warning! All relevant electrical safety precautions should be taken when connecting mains power supply to the relay contacts. With the help of single pole double throw (SPDT) switch S1, internal or external trigger input (active high signal) can be selected.

Monday, November 3, 2014

Battery Juicer

More and more electronic devices are portable and run off batteries. It is no surprise, then, that so many flat batteries find their way into the bin and often far too early. When a set of batteries can no longer run some device for example, a flashgun the cells are not necessarily completely discharged. If you put an apparently unserviceable AA-size cell into a radio-controlled clock with an LCD display it will run for months if not years. Of course not every partially discharged cell can be put in a clock.

The circuit presented here lets you squeeze the last Watt-second out of your batteries, providing a bright ‘night light’ - for free! The circuit features a TBA820M, a cheap audio power amplifier capable of operating from a very low supply voltage. Here it is connected as an astable multivibrator running at a frequency of around 13 kHz. Together with the two diodes and electrolytic capacitor this forms a DC-DC converter which can almost double the voltage from between four and eight series-connected AA-, C- or D-size cells, or from a PP3-style battery.

Battery Juicer Circuit Diagram:

The DC-DC converter is followed by a constant current source which drives the LED. This protects the expensive white LED: the voltages obtained from old batteries can vary considerably. With the use of the DC-DC converter and 20 mA constant current source a much greater range of usable input voltages is achieved, particularly helpful at the lower end of the range when old batteries are used.

With the constant current source on its own the white LED would not be adequately bright when run from low voltages. An additional feature is the ‘automatic eye’. The LDR detects when the normal room lighting is switched on or when the room is lit by sunlight: its resistance decreases. This reduces the UBE of the transistor below 0.7 V, the BC337 turns off and deactivates the LED.

This prolongs further the life of the old batteries. A further LDR across capacitor C reduces the quiescent current of the circuit to just 4mA (at 4V). Light from the white LED must of course not fall on the LDR, or the current saving function will not work.

Sunday, November 2, 2014

HANDY 0 12V DC POWER SUPPLY ELECTRONIC DIAGRAM

HANDY 0-12V DC POWER SUPPLY ELECTRONIC DIAGRAM

For heat protection, heat sink is needed for the BD679 transistor. It is because it will be over tempered when works more than 200mA.

FEATURES:

0v to 12 volt output:

- 700mA with M 2155

- 1.4amp with M 2156

- 1A with 16v AC 1.5 amp plug pack

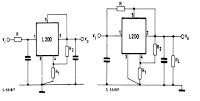

RESISTOR TO REDUCE L200 POWER DISSIPATION ELECTRONIC DIAGRAM

RESISTOR TO REDUCE L200 POWER DISSIPATION ELECTRONIC DIAGRAM

Instead of in series with the input, the resistor R can be connected between pins 1 and 2 of the IC if the load is constant. You can see this in the right figure. This will make some part of the load current flows through the resistor and the other part through the device.

Digital 100W RMS Amplifier Circuit Diagram

This is a Digital 100W RMS Amplifier Circuit Diagram.This is a 100 watt basic power amp that was designed to be (relatively) easy to build at a reasonable cost. It has better performance (read: musical quality) than the standard STK module amps that are used in practically every mass market stereo receiver manufactured today. When I originally built this thing, it was because I needed a 100 WPC amp and didnt want to spend any money. So I designed around parts I had in the shop.

Digital 100W RMS Amplifier Circuit Diagram

The design is pretty much a standard one, and Im sure there are commercial units out there that are similar. To my knowlwdge, it is not an exact copy of any commercial unit, nor am I aware of any patents on the topology. To experienced builders: I realize that many improvements and refinements can be made, but the idea was to keep it simple, and should be do-able by anyone who can make a circuit board and has the patience not to do a sloppy job.

The input stage is an LF351 op amp which provides most of the open loop gain as well as stabilizes the quiescent dc voltage. This feeds a level shift stage which references the voltage swing to the (-) rail. The transconductance stage is a darlington, to improve high-frerqency linearity. The 2SC2344 by itself has a rather large collector-base capacitance which is voltage dependent. The MPSA42 presents this with a low-z and has a C(ob) of only a few pf that is effectively swamped by the 33pF pole-splitting cap. The stage is supplied by the 2SA1011 active load (current source) which is about 20 ma. The current to the stage is limited by the 2N3094 to about 70 ma under worst case.

The output is a full complementary darlington with paralleled outputs. Although you could "get away with" only one if only 8 ohm easy-to-drive loads are used, this is not recommended. The use of parallel devices increases the ability to drive reactive loads (which can pull a significant current while the voltage waveform crosses zero and puts a high voltage and a high curent across the transistor simultaneously), gives the amp a higher damping factor, and reduces the maximum current each transistor has to supply to peaks (remember, the gain of a power transistor drops as the current increases).

Compensation is two-pole and one zero. The op-amps pole and the pole generated by the 33pf cap and the 470 ohm bias resistor of the MPSA42 dominate. (the 33pF gets multiplied by the stage gain.) The 22 pf feedback capacitor provides lead compensation, and is taken from the output of the tranconductance stage rather than the output itself. In this way, the phase lag introduced by the output transistors is not seen by the high-frequency feedback. This intorduces a closed-loop pole which limits the high-frequency response. The two compensation capacitors must be type 1 creamic (NPO) or silver mica - with ZERO voltage coefficient.

The amp was designed to run 2 channels off a +/- 55 volt unregulated supply, reducing to +/- 48 volts under full load. It used a 40-0-40 volt, 5 amp toroid transformer, a bridge rectifier, and 10,000 uf of filter cap per side. If a standard EI transformer is used, a 6-amp rated unit should be used. With this power supply, it produces 100 watts continuous, both channels driven into 8 ohms resistive with no clipping. Dynamic headroom is about a db and a half. For more headroom, unloaded voltages to +/- 62 volts can be used with no circuit modification.

By the way, the schematic is in Postscript.

Limitations:

With no modifications the amp will drive 4-ohm speaker systems with no current limiting. The short-circuit current limit is set to about 4.5 amps peak, which will handle conventional speaker loads.(It will, of course, produce higher peak currents as the output voltage swing approaches the rail.) If you are going to be running some of those high-end speakers with impedance minima of half an ohm, or that stay reactive throughout most of the audio band ( ie, 0.5 +j3.2 ohms) you will probably already own a better amp than this. If the higher-power Motorola power transistors are used, it will drive a 2-ohm resistive load without problems (except heat).

I have never heard any slew-induced distortion on this amp with a CD players band-limited (22KHz) signal. I suppose that real high-end freaks could pick it to pieces by hitting it with a TTL square wave mixed with a 19KHz stereo pilot tone and crank it up. I guarantee that there will be spurs all over the spectrum, but who listens to that?

Possible Modifications: (What if I want mo power???)

The Toshiba output transistors (2SD424/2SB554 pair) shoud not be used with supply voltages above +/-60 volts. If you plan on cranking it up, use more in parallel or use the 250 watt Motorola pairs (MJ15024/MJ15025). If very low impedances are expected, raise the bias in the transconductance stage to give more base drive to the output darlingtons or add another current gain stage. Higher-Beta (and faster) power transistors cant handle reactive loads worth a crap. Dont substitute high-fT parts unless you are sure they have adequate second-breakdown capability.

The NE5532 op-amp can be used in the input stage. If more than one are used off the +/-15 volt shunt regulators (balanced ins, anti-slew Bessel filters, etc.) the 2.7K dropping resistors may need to be reduced to say, 1.8K ohm to maintain regulation. The 2.7K resistors will allow up to 4 LF351 type op amps off the regulator (I used a quad 347 for balanced inputs to avoid hum in a DJ setup).

Construction tips:

The output transistors and thermal compensator (2SC1567) will need to be mounted on a common heat sink - a finned unit measuring 5 in. high by 8 in. wide with 1.25 in fins should do nicely for one channel. (They look nice if you make the sides of the case out of them). Most normal applications wont require more cooling than this. The reason the 2SC1567 was chosen for the output bias regulator is because it is fully insulated - the ECG version will require additional mounting hardware. TO-3 hardware for the outputs is cheap and easy to get.

The driver transistors and voltage amps (2SC3344/2SA1011 pairs) will all require heatsinking as well. Individual TO-220 heat sinks on the circuit board will suffice - the voltage amps dissipate about 1.4 watts each. A common piece of 1/8 in. thick 1 in. wide X 4in. long angle aluminum will suffice for all 4 on each channel, but bear in mind that it must be oriented to take advantage of natural convection, and the transistors must be insualted.

Keep the imput grounds separate from everything else, and return them at ONE point. Failure to do so WILL result in high distortion (5% or so), or even oscillation.

The output stage bias should be set to about 25 milliamps in the output transistors. This value takes a while to stabilize, and you may have to monitor it over an hour or so during initial setup. To measure it, measure the voltage across the emitter resistor and use Ohms law. This way, you can check the current sharing in the parallel output transistors at the same time and change them if there is a serious discrepancy. With parts of the same date code, they should not be off by more than 10% after it has warmed up. Higher output stage biases can be used, but it takes more care in setting it. If you want an idle current of more than 50 milliamps per side, increase the value of the emitter resistors.

Initial Checkout:

DO NOT just plug something like this in! A seemingly insignificant error can set your house on fire! (As well as blow out $30 worth of transistors in a microsecond.) A variac will work in theory, but the amp may latch to the rail if the supply drops too low. I suggest the use of a ballast resistor - a 60 to 100 watt light bulb in series with the AC mains. You get a bright flash when the caps charge, and then it goes (almost) out as the idling supply current reaches its nominal low value. The amplifier will then work normally at low volumes. If the amp draws too much current for whatever reason, the lightbulb will glow brightly, increase resistance, and limit the power to the circuit. Usually, there will either be a mis-wire (use your DMM) or oscillation (will show up on a scope or RF power measuring device). If the bulb goes dim-bright-dim-bright... then the amp is marginally stable and the grounding layout should be checked. Compensation capacitor values may need to be adjusted if any significant changes were made. Mine is stable the way it is.

Additional Notes:

The schematic is in postcript, so it should just be able to be printed out. The emitters of the transistors are labelled by an "e". I was too lazy to put arrows on the transistor symbols - and Ive been using it that way for over a year now.

Trouble finding parts? MCM (1-800-543-4330) has all the transistors. Total cost for a stereo version should be between $150 and $250, depending on what kind of bargains you can find on the case, transformer, and heatsinks. If you have to pay "list" for everything, it will likely cost about $1000 to build.

The information included herin is provided as-is, with no warranties express or implied. No resposibility on the part of the author is assumed for the technical accuracy of the information given herein or the use or mis-use of said information.

The equipment described in this article was designed, fabricated, and tested on my own personal time using my own personal resources.

Author:, warren@eggo.csee.usf.edu